About Global Lift Used Forklifts Pasadena

Global Lift Pasadena - Regardless whether you have a brand new forklift fleet or second-hand forklifts, your equipment has to be maintained to ensure productivity and safety. Careless forklift operation can lead to additional expenses due to abuse and damage. There are easy ways to identify operator practices that indirectly contribute to expenses related to the wrong operation of Caterpillar lift trucks or forklifts. The following suggestions will help you lessen operating expenses while ensuring a long life for your machinery.

Regardless whether you have a brand new forklift fleet or second-hand forklifts, your equipment has to be maintained to ensure safety and productivity. Careless forklift operation can result in added expenses due to damage and abuse. There are simple ways to identify operator practices which indirectly contribute to expenses associated to the improper operation of Caterpillar forklifts or lift trucks. The following tips will help you lower operating costs while ensuring a long life for your equipment.

Causes Of Facility and Forklift Damage

Wrong Forklifts. Choosing the right lift truck equipment for the application is essential for efficient and safe forklift performance. One of the most common mistakes is utilizing the wrong type of forklift or options for the particular job. Machinery can suffer premature wear and tear. Parts can be subject to failure. Check that the lift truck is fitted with the correct tires and that they are not worn.

Improper Forklift Operating Practices. Improper forklift operating practices are a common cause of impact damage. Damage to product, equipment or facilities could take place while navigating around products. A congested work place lends itself to impacts. For example, pushing pallets, called "Bulldozing", can wear tires and damage the transmission.

Unsafe Forklift Speeding and Lifting. Equipment damage and personal injury could happen by improper lifting practices. Common errors comprise lifting very high and traveling very fast. A load that is very heavy could cause the forklift to tip over. The operator must make sure that the forks are level.

Forklifts have been an important tool in commercial businesses and industry ever since 1917. Throughout its history the forklift has changed through various forms, from a basic tractor with an attached platform to a particular high-tech equipment. Forklift tires have also changed into particular tires, with different types designed to meet specific functions.

A cushion tire is constructed of solid polyurethane or rubber and is best for indoor work on smooth surfaces. The cushion tire tread is bonded or pressed onto the steel ring of the tire. Cushion tires are rated ease of steering and for various load capacities. Cushion tires are normally utilized in warehouse settings.

Air or foam is utilized to fill pneumatic forklift tires. They come in two types: radial or bias. Depending on the use, they are offered with various sidewall protection, tread depths and weight. Pneumatic forklift tires which are filled with foam maintain constant pressures and are less susceptible to punctures. Pneumatic tires are normally used outdoors on surfaces which are uneven and rough.

Solid Pneumatic Hybrid tires combine the puncture resistance of a solid tire with the comfortable ride of a pneumatic tire. They are a great option to the outdoor pneumatic tire.

Big rubber tires, that could be pneumatic, foam or solid, are used on wheel loader forklifts. These tires are suitable for moving and loading bulk things into processing equipment or onto trucks. Large flotation pneumatic tires are suited for masted rough terrain forklifts commonly used at construction locations, auto recyclers and lumberyards.

Nearly all businesses want a reach truck which helps them get the job done fast and efficiently. At the end of the day, these are among the important elements which would allow the business to earn the most money. The Crown series of reach trucks offers you with more for your investment in various ways. Like for example, these machinery deliver responsive controls together with smart traction. The state-of-the-art ergonomics offer the operator with a major edge.

These narrow aisle reach trucks could attain great capacities, visibility, heights and energy savings. Crown's machines offer numerous durable and reliable machines that could endure harsh environments. They provide precise load handling and increasing pallet moves with phenomenal lift and travel speeds. The reliability is well documented and leads to driving overall expenses down while offering industry-leading uptime and maintenance simplicity.

The SR 5000 Series, the RR 5700 Series and the RM 6000 Series make up the reach truck series manufactured by Crown. Specifically, the Crown RR 5700 delivers the best performance in the reach truck industry for travel and lower/lift functions.

The RD 5700 is a productive workhorse of a machinery which also offers great durability. This particular model offers optimal utilization of space without losing any operator comfort. The most innovative performance and design as well as innovative technology all come together in this series. Crown also offers their exclusive Access 123 Comprehensive System Control to offer great service team accessibility and operator control.

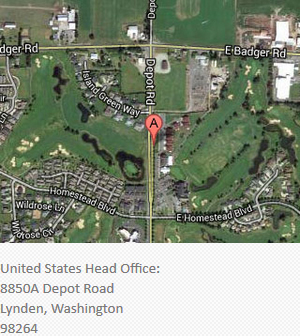

Contact Info

Questions or Comments